This is a guide through the components, construction, protection, maintenance and treatment of a farm water well. A step by step procedure for sealing and decommissioning old or abandoned wells is given and symptoms of water well deterioration are also outlined.

Water well components

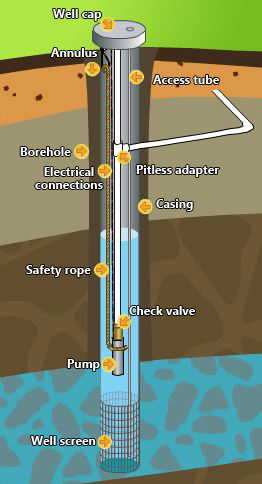

To successfully construct or maintain a well it is important to have a good understanding of its components.

Description of above image

The well cap covers the top of the well casing with a tight seal and prevents contaminants, vermin and debris from entering your well. The cap also allows for venting, locking and easy access for well inspections.

The access tube is a plastic pipe or hose installed in the well. It is used for measuring water levels in the well. An access port built into the well cap allows easy access to the access tube.

The pitless adapter provides a watertight sanitary removable connection between the discharge line from the pump and the water pipeline to the house.

A safety rope is attached to the submersible pump and secured at the top of the well.

The electrical connections enable power to be supplied to the well pump. Conduit seals, cable ties, watertight splices and cable guards are components of the electrical connections.

The borehole is a hole that is drilled into the ground to allow for a well installation.

The casing is a solid pipe placed above the well intake area (that is perforated liner, well screen) which keeps the borehole open and houses the pumping equipment. It usually consists of plastic, steel or fiberglass.

The annulus is the space between the borehole and the well casing. This space must be sealed with impervious material such as cement or bentonite to prevent any surface contamination from migrating downward and contaminating underlying aquifers.

The check valve is located at the top of the pump to hold water in the tank and prevent backflow through the pump. It also helps to maintain a high pressure in the water supply line.

The pump is a machine capable of lifting, raising or moving water from a well or tank to a higher elevation or a distant location. A pump can create pressure and/or increase the velocity of water.

The well screen, also known as a perforated liner, allows water to enter the well casing while preventing aquifer materials from entering the well.

Well construction

Proper well construction is critical for a healthy, sustainable water supply. Well construction can be quite complicated and requires much knowledge in this area.

Please refer to the Water Wells That Last manual which contains information on how to construct a well.

Wellhead protection

Wellhead protection means implementing practices that will protect the well and the surrounding area from contamination. It will also protect the structure of the well and ensure a safe, long-term water supply.

There are six main components of wellhead protection for domestic rural wells:

- Siting wells

- Constructing wells properly

- Keeping contaminants away from wells

- Preventing backflow

- Sealing unused wells

- Testing well water

Siting wells

Siting a well means to find a suitable location to drill a well. When looking for an area to drill a well, avoid low lying areas. You must consider the placement of the well relative to several items found in your yard. These items are called setbacks because the well should be "setback" a safe distance from these items.

A well should be setback from:

- any building

- overhead/buried power lines

- road allowance

- septic holding tank and infiltration area

- manure storage and livestock pens

- fuel tanks

- cultivated fields

- chemical storage areas

The setback distances from a well depend on which province you live in, so you will want to find out what is required for your province. See the Well sealing and decommissioning section for links to the provincial regulation websites.

Constructing wells properly

The proper construction of a water well helps to prolong the life of a well and reduces the risk of groundwater contamination. There are several things that you can do to ensure that your well is constructed correctly.

- Before any construction begins be sure to observe all recommended setback distances for your province so that you find a good location for your well.

- Before you hire a professional to drill your well, do a little research to ensure they have the necessary credentials and experience.

- Ensure that the driller will guarantee provincial regulation compliance, workmanship and materials used.

- Once the well is completed, get the well completion details from the driller so that you understand how your well was constructed. For more details refer to the Well construction section. Also, make sure that the well annulus is sealed.

- This is the area that is between the well casing and the wall of the hole that was drilled.

- Ensure the well casing is extended above ground and fitted with a secure, water-tight well cap, and that the area around the wellhead is mounded.

- Finally, you will want to perform a pump test on a regular basis and also keep a construction record that includes when it was built and any modifications made to the well.

Keeping contaminants away from wells

It is essential to keep contaminants away from your well to keep the water safe to use and drink. There are several common contaminants that can be found around a farmyard.

Chemicals such as pesticides and fertilizers that are used in your yard can contaminate a well, so avoid using them near the well area. Also ensure that you keep their storage and mixing areas a safe distance away. You will also want to take extra care to keep a safe distance from the well area when using machinery that is spreading manure, chemicals, fertilizers, seeds or other possible contaminants.

Household chemicals and medicines can also be sources of contamination. Ensure that you dispose of them properly by contacting your nearest chemical recycling agency. The improper storage of gasoline and oil can cause contamination. Store them away from the well in leak proof containers that cannot be broken. Be sure to dispose of unwanted oil properly, by contacting your nearest oil recycling agency. Some other contaminants are waste disposal pits, livestock burial pits, livestock pens, manure and household septic tanks. Be sure to keep all of these away from your well and water source.

Preventing backflow

Another way to protect your well is to prevent backflow. Backflow occurs when contaminated water flows backwards through your plumbing into your well. Some backflow sources are washing machines, laundry tubs, lawn irrigation, green houses, chemical containers and mixing tanks, livestock watering bowls, and water supply systems that use multiple sources.

Proper maintenance including regular cleaning and inspections of the check valves can help prevent backflow from occurring. A check valve is a valve that has two openings and allows fluid to flow through in one direction only.

Sealing unused wells

Another way to protect your water source from contamination is to seal any abandoned or unused wells on your property.

If an abandoned well is not sealed properly, the casing can degrade with time and allow surface contaminants direct access to the groundwater. Old wells can also allow cross contamination between two different aquifers. For more information about abandoned wells visit the Plugging Abandoned Wells site.

Testing well water

It is important to regularly test the quality of water in the well. Some of the most common tests are for bacteria, nitrates, conductivity and metallic ions such as iron, manganese or arsenic. You should test the water on a regular basis, however, there are also signs to watch out for that should alert you that conditions in the well have changed. If you notice any changes in the water you should test the well right away.

Watch your tap water for changes in:

- cloudiness

- colour

- taste

- odour

If you notice a change in water quality, inspect the wellhead area for:

- casing damage

- ground settlement

- animal activity

- change in land use practices

Even with good siting and construction, a well may become flooded. If this happens, the well should be flushed, disinfected, and tested for contaminants before using it again. It is important to act in advance to protect the wellhead. Carrying out these steps will help prevent contaminants from entering the water well supply, avoid having to use expensive treatments to fix problems that could have been prevented and protect the investment in the drinking water supply.

Preventative well maintenance

A preventative well maintenance program can extend the working life of a water well and ensure that suitable water quality is as good as reasonably possible. Maintenance is the responsibility of the well owner and consists of regular inspections, monitoring, and scheduled treatments. Assistance with these preventative maintenance procedures can also be provided by specialists in the water well industry.

Regular inspections

Regular inspections are one way to prevent your well from damage or contamination. Checking your well on a regular basis allows you to identify problems early, making it easier and less expensive to fix the problem. Regular maintenance also helps prevent more serious problems.

- Check to ensure that the wellhead extends above the land surface and that the area around the well is sloped away to prevent water ponding near the well.

- Secure and lock the well cap so that there are no holes or gaps where insects and rodents can enter. Also check for sources of contamination near the well (for example livestock manure, oil tanks, fertilizers and other chemicals, septic field).

- Ensure the well vent screen is properly placed and secured.

- Monitor water quality for changes which may indicate problems with the well installation or aquifer. Record any changes in turbidity, taste, odour and colour.

- Check to ensure backflow devices are in place and functioning.

- Remove the well cap and check the well.

- Do a visual inspection of the inside of the well with a flashlight and keep a video log of your inspections so that you are able to easily recognize any changes.

- Besides regular inspections, the well owner can conduct other activities regularly to help prevent future problems in the well.

- Keep the area around the well clear by mowing or gravelling. Avoid chemical applications around the well.

- Seal any cracks or unused openings in the well casing and concrete pad surrounding the well.

- Remove the well pump for inspection and check for any slime or mineral build-up on the pump.

Regular monitoring

Another way to keep your well in good shape is by monitoring it regularly. Regular monitoring consists of examining and recording the information about a particular item on a regular basis. This information is then compared to the previous record to see if there have been any changes.

- Measure and record the pumping and non-pumping water levels in the well. Record the pumping rate (for example 5 gallons per minute).

- Calculate the drawdown (that is non-pumping water level minus the pumping water level) to determine if the well is becoming plugged. If the pumping rate is the same (for example 5 gallons per minute) but there is an increase in the drawdown, it is an indication that the well screen may be starting to plug.

- Monitor the water chemistry on a regular basis and also conduct microbiological testing. Changes in water chemistry and positive tests for coliform bacteria are symptoms of well problems.

- Check the interior of the well for any unusual colorations and disturbances that may indicate deterioration. Record your findings so that on the next inspection you can compare the results and determine the status of the problem.

Maintaining records

Keeping detailed and accurate background information and maintenance records provide the information necessary to make informed decisions that will help to extend the operational life of the well. There are many kinds of information that should be included in these records. The following check lists will help you along.

Background information

- Background data: driller's well log; well pump design

- Non-pumping and pumping water levels

- Results of well pumping tests

- Well production rates

- Water quality analysis

- Results of well inspections

- Repairs/replacement of well components

- Scheduled maintenance

- Location of adjacent wells/abandoned wells

Diagnostic work

- Gather well construction and background information

- Measure the present static (non-pumping) and pumping water levels in the well

- Evaluate any change in water levels, well yield or specific capacity over time

- Sample water directly from the well for biological and chemical analysis

- Evaluate any change in water chemistry or biological activity over time

- Document all well treatments

Optional procedures

- Inspect for scale or slime deposits on the pump

- Video/camera log the well casing and screen

- Pump test the well to establish a well performance baseline prior to treatment

- Check the pump motor

- Inspect the pump wiring

Scheduled treatments

It is important to schedule regular shock chlorination treatments for the well and plumbing to minimize the impact of microbiological fouling, since we already know that the microbiological fouling can affect both the well yield and water quality.

Shock chlorinating a well involves preparing a solution of chlorine and water and then siphoning or pumping the chlorine solution down the well. This process is used to eliminate or control the population of bacteria in a water well.

Most wells require shock chlorination at least once a year, but some may need it more often. How often it is required depends on the water chemistry, well construction and operation, and the surrounding well environment. If it is applied properly, shock chlorination has no detrimental effects on a well.

Rehabilitation

Regular well maintenance will slow the onset of most well problems. However, if problems develop, monitoring and record keeping will provide the information necessary to identify the cause of the problem and choose the most effective treatment.

While various means of chemical and mechanical rehabilitations are available, implementing these measures requires the services of an experienced well drilling or servicing company.

Sometimes a well can deteriorate to the point where it can no longer be fixed. If you can provide the professional with enough background information, they should be able to evaluate the likelihood of a successful rehabilitation.

You should rehabilitate your well before there is a serious loss in well yield or deterioration in water quality. Biofilms and chemical scale are easier to remove when they are young and soft rather than old and hard.

Be sure to evaluate the well yield and water quality both before and after the treatment, this will give you an indication of how successful the rehabilitation was.

Remember proper maintenance, like home or car maintenance, can prolong the life of your well. If you cannot maintain your own well, a contractor can be hired to do so.

Well sealing and decommissioning

Decommissioning a well, or sealing it, is to fill a well with the proper material in order to avoid groundwater contamination. A well should be sealed if it is no longer possible or probable that it will ever be used as a water supply. Any well that has been unused for more than a year is a potential candidate for sealing.

Reasons for well sealing

If not properly filled with impermeable material, an unused well can act as a direct pipeline for contaminated water from the surface to enter the groundwater below.

Contaminated surface water from spring run-off or flood events can enter a well directly through the top of the casing if the well does not have a protective lid and if the casing does not extend high enough above the ground surface. Open wells can also offer tempting disposal sites for liquid or solid wastes.

Undesirable surface water that enters the well directly through the top of the casing bypasses the purifying action that normally takes place in the upper layers of the soil. Contaminants that enter unused wells can move to nearby active wells.

Large diameter water wells that are no longer in use are a significant physical safety hazard. Humans or animals can fall down a well that does not have adequate surface protection.

Not all hazards are visible from the surface. Depending on the age and construction of the well, there may be unsealed spaces between the outside of the casing and the original drill hole (annulus) that can allow undesirable surface water to seep down alongside the casing into the aquifer.

An old well may have a rusted-out casing below ground which can allow surface contaminants from septic systems, barnyards or fuel tanks to be carried by shallow groundwater into the well.

Requirements for well sealing

The requirements for well sealing in Canada depend on which province you live in. There are differences between each of the provinces and territories as to the regulations and policies that deal with inactive water wells and the appropriate way of decommissioning them.

There are agencies in each province that can provide technical guidance on proper well sealing techniques and procedures:

- British Columbia: Groundwater Wells

- Manitoba: Water Stewardship Division

- Newfoundland and Labrador: Water Resources Management

- Nova Scotia: Groundwater – Environment

- Ontario: Water - Ministry of the Environment

- Prince Edward Island: Department of Agriculture and Fisheries

- Saskatchewan: Water Security Agency

Well sealing preparation

There is a certain amount of preparation to be completed before the sealing requirements for a well can be properly assessed. If you do a bit of research before contacting an agency it can help speed up the process of assessing it. Determine the answers to as many of these questions as possible and make notes of your findings.

- Measure the well to figure out both the depth (height) and diameter (width) of the well and the casing (if any).

- Determine if the well has ever been modified or reconstructed.

- Determine what the water level or range of water levels in the well are by measuring it as recommended in the Preventative well maintenance section. Also make a note if the well has ever flowed.

- Check if there are any obstructions in the well, including old pumps and plumbing.

- Determine if the well has ever been contaminated.

- Determine if there are any well records, including any oral recollections by well owner or neighbours.

- Does the well intercept any other water bearing formations? For example, is it deeper than other nearby wells?

Once you have answered as many of these questions as possible, you will be able to determine the best way to proceed with the well sealing. The answers to these questions also allow technical experts in your province to determine the best method for proper well sealing.

Well wealing

There are many different types of wells which require specific procedures for sealing.

Some of these well types are:

- Artesian or flowing wells

- Wells with known contamination

- Wells with obstructions or a collapsed casing

- Wells that intercept more than one water-bearing unit

- Wells that are greater than 30 meters in depth

If your well has any of these characteristics you may encounter problems when trying to seal it. We recommend that you contact an agency to assist you with the decommissioning of the well.

When decommissioning a well, the intent is to fill and seal the well in a manner that will prevent the vertical movement of water within the well column and prevent any movement of contaminants into surrounding aquifers.

Requirements for well decommissioning vary from province to province. It is generally recommended that an experienced water well driller be hired to complete the well decommissioning process.

One of the first steps is to check to see if the well is clear to the bottom. The well should be disinfected with a chlorine solution and cleaned or flushed. Some provinces require the surface casing to be removed (or pulled) which would require the use of a drilling rig. Materials that are used to seal a well must be impervious. Sand and gravel are not acceptable materials because water can easily move through them. Bentonite grout is one of the most common materials used to seal wells.

Bentonite grout or cement (no aggregate) can be mixed as a slurry and pumped into the well. The slurry should be introduced at the bottom of the well with the use of a tremie pipe and the well should be filled progressively upwards. A tremie pipe is a small diameter pipe placed inside the well casing and used to carry material to the bottom of the well. Pouring or dumping the materials into the well from the top or through a tremie pipe that is not long enough could cause the material to become diluted or bridged in the well part way down. If dilution occurs, the fill material will not be impermeable. If bridging occurs, the well will only be partially filled.

Another material that is used to prevent vertical movement of water consists of small, coated bentonite pellets or "chips." The pellets are designed and manufactured for the purpose of being introduced into the well from the ground surface. When poured slowly into the well, they reach the bottom before swelling and closing off the hole. If poured too quickly, bridging can occur some distance above the bottom of the hole.

Generally, it is possible to seal most large diameter wells (those that were originally completed by excavation or auger) with locally available materials and equipment. Many large diameter wells and small diameter wells of less than 30 metres in depth can be sealed by the well owner, however, the proper sealing materials and techniques are subject to provincial regulations.

There are financial and technical advantages for arranging to have a number of wells sealed within an area. These initiatives are usually coordinated through local municipalities and non-government agencies.

Water well deterioration

All wells can lose capacity over time due to natural or induced processes. These processes can be prevented or controlled through regular monitoring and scheduled preventative treatments. Understanding the processes is important when diagnosing well problems.

Symptoms

Well deterioration can affect both the quality and quantity of water produced from a well, and is generally caused by biological activity, mineral accumulation/chemical encrustation, physical plugging or a combination of these processes.

Some water well deterioration symptoms are:

- A loss of production, due to increased drawdown (lower water level in the well during pumping)

- Changes in water quality

- An increase in the amount of dangerous bacteria in your water

- Unusual or pungent odors coming from your water

Physical plugging

Physical plugging occurs when fine grained aquifer materials are drawn to the well and accumulate in the area around the well screen. Overpumping can cause plugging. When the pump runs too hard, fine particles move from the aquifer towards the well. These particles can plug the screen and pump and may affect the water quality. Also, if the pump runs too often, the water cannot replenish itself fast enough causing the pump to work improperly. Corrosion of the well casings and screens allows large quantities of sand to enter the well leading to pump failure.

When a well or pump becomes plugged with fine particles the well will need to be flushed out and the pump serviced. Installing a flow restrictor on the pump and increasing the time of pump operation will help avoid overpumping. If this does not work then it may be necessary for a person to physically unplug it and repair the pump.

Mineral accumulation

Well screens and pumps can also become plugged due to mineral accumulation, encrustation and scaling. There are several factors that can cause this kind of plugging:

- When there become more dissolved minerals in the water than usual, they can clog up the screen.

- When the water level drops too low, it can cause aeration (air entering the holes) at the well screen.

- When water is flowing faster than normal, the force can cause minerals to build up on the screen.

- Water can contain gasses that can cause mineral build up. These gasses are similar to bubbles in a soda.

- When there is a change in the amount of chemicals that are in the water.

- An increase in iron causes build up because when iron minerals join with the oxygen chemical, they swell.

Bacteria

Activities associated with natural groundwater bacteria can cause or accelerate well plugging and can affect water quality. This biological activity is called biofouling.

The first step is the colonization of bacteria on surfaces in and around the well screen. Secondly, the bacteria make slime, or biofilm, which accumulates on the well screen. Finally, as the amount of slime grows, soil and mineral particles get trapped within the slime causing the screen to clog.

Biofouling is occurring if there is an increased population of nuisance bacteria and an increased drawdown is observed in the well. If there are strange odours in the water, a change in water colour or increased turbidity it could be a sign that biofouling is occurring. A build-up of slime on the pump and the discharge line is another sign of biofouling.

The best way to prevent biofouling is to monitor and disinfect your well on a regular basis. If a problem does develop, there are procedures that can be used to evaluate the problem and determine the best solution.

Glossary of terms

- Annulus

- the open space between the casing and the side of a well.

- Artesian or flowing wells

- a well that has a static water level above the surface of the ground, causing the well to flow.

- Aquifer

- an underground layer of porous, saturated soil or rock that is capable of yielding a useful supply of water.

- Bentonite

- a swelling clay made up of the mineral sodium montmorillonite, a hydrated aluminium silicate.

- Biofouling

- the gradual accumulation of waterborne organisms (as bacteria and protozoa) on the surfaces of engineering structures in water that contributes to corrosion of the structures and to a decrease in the efficiency of moving parts.

- Bridge

- an obstruction in the drill hole or annulus.

- Conductivity

- estimates the amount of total dissolved salts (TDS), or the total amount of dissolved ions in the water by measuring the flow of electrical current throught the water.

- Coliform

- a common group of bacteria found in animal wastes, surface soils and vegetation whose presence in well water can indicate water contamination.

- Contamination

- the degradation of natural water quality as a result of human activities.

- Decommission

- to remove a well from service.

- Discharge

- the flow of surface water in a stream or ditch or the flow of groundwater from a spring or flowing artesian well.

- Disinfection

- the process of eliminating nearly all disease-causing organisms from water.

- Drawdown

- the distance between the static water level and the surface of the area of influence of a well.

- Groundwater table

- depth at which all the pores are saturated.

- Groundwater

- water beneath the surface of the earth in the pores and fractures of sand, gravel, and rock formations.

- Grout

- a material such as bentonite, mixed with water to form a watertight barrier, used to fill and seal the annular space.

- Impermeable

- not permitting passage of a fluid through rock, sediment or soil.

- Oxidation

- the combining of an element with oxygen.

- Recharge

- replenishment of the groundwater by the addition of water.

- Runoff

- that part of precipitation flowing to surface streams.

- Shock chlorination

- involves adding a large amount of chlorine to the water in the well and pumping it through the system; the chlorinated water is left in the system long enough to ensure complete disinfection.

- Slurry

- a thin mixture of liquid, especially water, and any of several finely divided substances such as bentonite, cement or clay particles.

- Submersible pump

- a centrifugal pump which is run by an electric motor and operates while submerged under water.

- Surface water

- water located on the surface of the earth in the form of ponds, stream, rivers and lakes.

- Total dissolved solids

- the sum of the weights of all mineral compounds dissolved in a specific volume of water.

- Tremie pipe

- small diameter pipe placed inside the well casing and used to carry material to the bottom of the well. Tremie pipes prevent bridging of materials and the diluting of liquid grouts.

- Turbidity

- a measure of the light-scattering effect of small particles suspended in water.

- Water quality

- the chemical, physical and biological characteristics of water with respect to its suitability for a specific use.