User friendly well design

In many cases, a rural farm well is not easily accessible for monitoring and for conducting regular preventative maintenance. A "user-friendly" well design will encourage regular monitoring and allow for the effective application of preventative maintenance treatments. Due to the design of the average farm well, conducting pump tests to obtain well performance data and to collect water samples directly from the well is difficult.

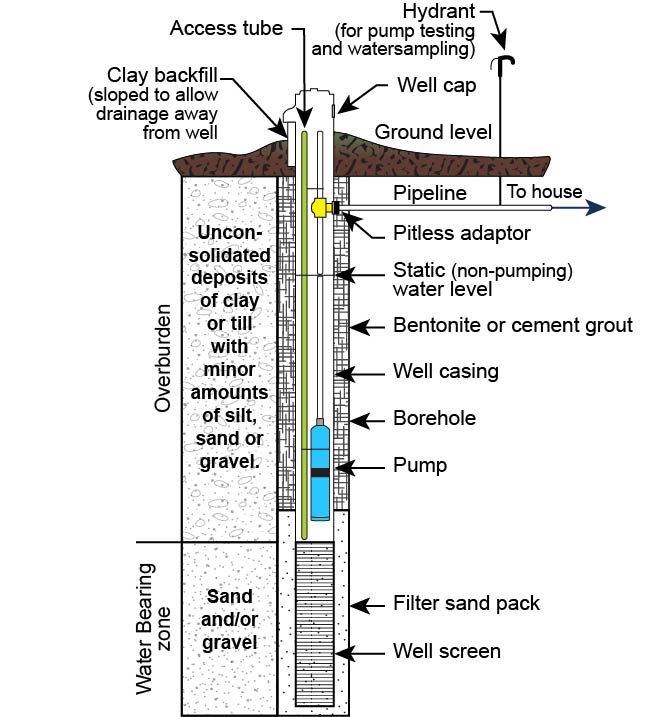

To overcome this problem, a hydrant can be installed in close proximity to the well, as shown in the adjacent drawing. This would facilitate the performance of periodic pump tests to collect specific capacity data and water samples, which are necessary data to forewarn of any potential problems.

Another simple design adaptation is to install an access tube that extends from just above the well intake area to the top of the well casing. The access tube could also have an appropriate fitting to allow connection of an injection pump as well as an air compressor. For preventative well maintenance, an access tube will allow treatment chemicals to be introduced directly into the well intake area, and could permit air-lift pumping to disrupt and remove plugging material from the well. A water level sounder could also be lowered down this access tube to monitor water levels in the well.

Description - User friendly well diagram

Figure is a cross-section of a well. Components illustrated are: pump, well casing, access tube and well screen. The well screen is in contact with water-bearing zone which is shown as sand and gravel. The borehole is packed with sand around the well screen and bentonite or grout in the unconsolidated material in the over-burden. Also shown are good management practices such as clay backfill on the soil surface that slopes away from the wellhead and a pitless adaptor that allows the well to be completely protected on the ground level. Water is diverted to the house with a pipeline which has a hydrant installed to allow for pump testing and water sampling.

Wellhead protection

A wellhead is the physical structure of the well above the ground and wellhead protection is simply the protection of the area surrounding the wellhead from contaminants that are likely to move toward or reach the well.

Pollutants spilled, or dumped on the ground, or pollutants seeping from a point source can enter the ground and eventually make their way into a well, and risk contaminating the well water and the aquifer source. Pollutants can include:

- Farm, household or industrial chemical storage

- storage and spreading of road salt

- use and spilling of fertilizers and pesticides

- accidental spill of hazardous materials

- septic tanks

- animal manure and wastes

- contaminants from rodents, insects or wildlife

- fuel storage

The contamination can result in an unsafe and/or unhealthy water source that may have to be closed down in extreme cases, or require additional treatment in order to be used. It can be costly and time consuming to clean up polluted groundwater or find new sources of clean water.

Groundwater contaminants can fall into three broad categories:

- Mineral/Metal Contaminants - including man made or naturally occurring inorganic chemicals;

- Microbial Contaminants - including bacteria, viruses and parasites;

- Synthetic Organic Chemicals - gasoline, pesticides etc.

Wellhead protection areas

Many municipalities across Canada have initiated wellhead protection areas for municipal wells as well as town wells. The amount of land that may be involved in a wellhead protection area (WHPA) is determined by a variety of factors such as land topography, the amount of water being pumped, the type of aquifer, the type and characteristics of the soil in the well area, and the direction and speed at which groundwater travels.

All of these factors are used to determine the area around the well having the greatest risk. This can be delineated by either a 100 metre radius, or where a two, five and 25 year "time of travel" is determined. A two year time of travel area is mostly concerned with bacteria, viruses, human and animal waste, and hazardous materials are of particular concern. In very general terms, in a five year time of travel area, biological contaminants are of less concern, while hazardous chemical may still be of concern. In the 25 year time of travel area, the most persistent and hazardous chemicals are a concern.

In the United States, and other provinces in Canada, several methods have been used to define wellhead protection areas. These methods can be as simple as selecting an arbitrary or calculated fixed radius, where no site-specific information is incorporated.

The next level of complexity would involve selecting a variable shape, which would include some site-specific information. In some areas, zones of influence are modeled using analytical or numerical methods that predict zones of influence based on several hydrologic parameters. The most reliable and most time-consuming and costly selection method would be hydrogeological mapping of the aquifer. These zones are most often mapped out based on the time of travel that it takes for water to move to the well under normal water extraction rates.

The use of time of travel zones is based on the assumption that the closer to the well a contaminant is introduced the less likely that it will be diluted or assimilated by the processes operating in the aquifer (adsorption, bio-degradation, decomposition etc.). Some provinces divide the zones using travel times of 100 to 250 days, 250 days to five years and five to 25 years as criteria. The approach is based on the level of risk associated with different activities and the nature of contaminants, which have different rates of movement and persistence in the environment.

Principles of wellhead protection

There are several basic principles of wellhead protection that should be followed to prevent the contamination of your well and the wells in your area:

Well location

Proper well location goes a long way toward preventing contamination of a well. Unfortunately, many well owners place a higher priority on convenience and cost when deciding where to drill a well. Wells should be located a safe distance (a set-back distance) from all present or future sources of potential contaminants. Set-back distances are regulated by provincial legislation and municipal by-laws. Where known sources of contaminants exist, locate the well in a direction opposite of the ground water flow (if known) and as far removed as the general layout of the premises and surroundings permit.

If possible, avoid locating a well in areas which are subject to flooding. If this is not possible, the well casing should extend at least 0.6 metres (m) (2 feet (ft)) above the level of the highest known flood of record. Avoid low-lying areas and depressions where standing water is likely to accumulate around the well. Install the well where surface water can be diverted away from the wellhead.

Well construction

When contamination occurs at a well site, it is usually the result of a pollutant entering the well either down the inside of the casing or around the outside of the casing. A well which is improperly constructed creates a direct conduit between the ground surface and the aquifer water supply.

Keeping contaminants away from wells

To reduce the chances of an accidental spill near a well, or contamination of soil around a well, maintain certain minimum horizontal distances between the well and sources of contamination. Most provinces in Canada have guidelines with respect to recommended setback distances from potentially hazardous sources of pollution. Here are some examples of potential contamination sources which might exist in vicinity of a rural groundwater supply:

- Septic tank

- Septic tank absorption field

- Dead animal burial pits

- Animal or fowl enclosures

- Pesticide storage, mixing and loading facilities

- Fertilizer storage

- Petroleum storage

- Sewage lagoon

Do not mix pesticides or discard empty pesticide containers near a well. Keep all such activities at least 30 m (check with your provincial agencies for appropriate setback distances) from the well. Never store pesticides or fertilizers in the pump house next to a well.

Use all household chemicals only for their intended purpose and properly dispose of the empty containers. Do not store or discard such items near your well site. Also, never dispose of excess household chemicals by flushing them down the toilet. The chemicals will enter the septic tank and could contaminate ground water in the area.

If you change the oil in your vehicles yourself, be sure to collect the oil in a container and carry it to a collection center for recycling. Some auto repair shops and service stations will accept used motor oil. Never dispose of the oil by dumping it on the ground.

Backflow prevention

Back-siphoning, or backflow, of concentrated pollutants is one of the more hazardous situations that can happen with a private well. The various ways backflow can occur can be prevented.

Backflow usually occurs when a well shuts off unexpectedly (power failure, lightning damage, etc.). When this happens, most private wells have a single check valve which prevents the water in the column pipe from falling back into the well. However, if the check valve leaks, and they often do, the water will flow back into the well, creating a suction throughout the water delivery system. If you were filling a pesticide tank with water when this happened and the end of the hose was submerged in the tank, a siphoning effect could be created and an entire tank of chemical could end up in your well.

This situation can be prevented by ensuring an air gap (never submerge the end of a water hose into any material which could contaminate a well). Better yet, install a simple atmospheric vacuum breaker on each outside faucet to prevent backflow. Many municipal water systems require that homeowners use these devices.

Many homeowners often use a hose-end device to apply fertilizers or pesticides to their lawn. These devices typically consist of a jar that holds the chemical and a proportioning device which attaches to the end of a water hose. Never leave these connected to the end of a water hose.

Backflow can also occur in lawn sprinkler systems. If one sprinkler happens to be in a low area with a puddle of water above it, this contaminated surface water could be siphoned into the well. Several devices can prevent this from happening, but one of the simplest and most common is a double check valve backflow preventer installed between the well and the irrigation system. You can buy these from any irrigation dealer and most plumbing suppliers. Injecting chemicals or fertilizers into your irrigation system creates a higher degree of hazard. This situation could call for a more expensive device called a reduced pressure zone principle backflow preventer.

Sealing abandoned wells

Many parcels of land have old abandoned wells. These wells pose a potential threat to operating wells in the area because they can serve as a conduit for contaminants at the surface to enter the aquifer. Never use an abandoned well to dispose of garbage or any other material which could contaminate ground water.

Many provinces have regulations or guidelines pertaining to the proper abandonment or decommissioning of wells that are no longer used. In some cases, well abandonment work is required to be performed by a licensed water well contractor.

Testing water quality and well performance

Rural water well supplies should be tested routinely to insure that no contamination has occurred, and that wells are still producing water at about the same rate as when the well was constructed.

A test for pesticides, petroleum products or other volatile organic chemicals is usually not needed on a routine basis. If you suspect contamination from any of these sources, however, these tests are available, but can be quite costly, if a full analysis is completed for a particular water sample. If a constituent is known to exist, a specific analysis may be considered.