Well rehabilitation comprises all measures that are undertaken to restore the functionality of a well, and generally consists of various treatments or redevelopment methods. The treatment method selected must be tailored to the problem, the well construction details and aquifer type.

The pump discharge pipe and distribution lines must also be cleaned when biological, chemical or physical plugging has occurred. Some degree of plugging is very common in wells and to be expected for many if not most wells. Some water supplies are more prone to plugging or biological growth (biofouling) depending on the water characteristics. Biofouling of wells can be very problematic for some owners. It is therefore critical that regular monitoring and preventative maintenance continue after well rehabilitation work has been completed.

Well rehabilitation is performed when the well has deteriorated to the point where preventative maintenance procedures no longer resolve well performance issues.

Well rehabilitation procedures are generally initiated when the well performance has declined by about 25 per cent, which points to the importance of collecting initial baseline performance data. When well rehabilitation is required it should always be performed by a licensed well driller or well rehabilitation specialist.

On this page:

Common well problems and basic rehabilitation approaches

No single well preventative maintenance treatment process or rehabilitation strategy will effectively solve every well problem. However, a qualified and experienced local well driller can be an excellent source of knowledge on common well problems in a specific geographical area. The driller should also be able to recommend appropriate treatment options and assist the well owner in selecting the best method of treatment and to determine if the treatment has been effective. This is done by performing a specific capacity test and comparing the results to pre-treatment conditions.

An understanding of the cause of the problem is required in order to identify the proper treatment method. The main causes of well problems are usually physical, chemical and/or biological plugging.

Severely plugged wells are difficult to restore to their original state.

The main objectives in performing a well treatment are:

- Achieve effective deposit removal

- Custom-tailor treatment method to the specific problem encountered, well construction details and aquifer type

- Good penetration into surrounding formation

- Good agitation of chemicals

The following factors should be considered when preparing for a well treatment:

- The pump must be removed and the well will be off-line for two to three days to complete the well treatment.

- Specialized equipment and trained personnel are needed to complete any rehabilitation work.

- Both chemical and mechanical methods are generally required for an effective cleaning.

- The type of deposit and physical condition of the well must be considered.

Well construction details and previous treatment or rehabilitation work should be reviewed.

| Common well problems | Solutions |

|---|---|

| Over pumping with No Evidence of Well Screen Plugging |

|

| Increased Microbiological Activity with No Decline in Well Yield |

|

| Corrosion or Structural Failure |

|

| Sand Pumping |

|

| Pump Failure |

|

| Plugging of Well Intake Area with a Decline in Well Yield |

|

General steps for well rehabilitation

The following are the general steps in a typical well rehabilitation process:

- Pre-Treatment Diagnostics: pump test, water sampling, pump removal/inspection, video inspection.

- Mechanical Cleaning: dislodge and remove mineral and bacterial slime build-up.

- Chemical Treatment: dissolve mineral incrustations and disrupt biological slimes for easier removal.

- Redevelopment: dislodge and remove spent treatment chemicals and plugging material.

- Post Treatment Diagnostics: compare to pre-treatment results to evaluate effectiveness of rehabilitation work.

- Chlorination: after rehabilitation has been completed, disinfect well and associated works.

Common methods for removal of mineral deposits and biofouling deposits

No treatment produces permanent results; expect deposition of minerals or biofilm to reoccur.

There are several methods that can be used to remove mineral or biofilm deposits from inside the well casing and well intake area. Some of the commonly used methods include mechanical and chemical removal. Although chemicals can assist in breaking down these deposits, chemical application should always be accompanied by some physical agitation to more effectively remove highly entrenched deposits.

Mechanical methods

Common methods include wire brushing, high-pressure jetting, surge block/swabbing; these methods are usually applied in combination with air-lift pumping to remove the loosened deposits.

Wire brushing

Wire brushing assists in the removal of mineral or biological build up, increasing the effectiveness of any chemical treatments applied.

Surge block/swabbing

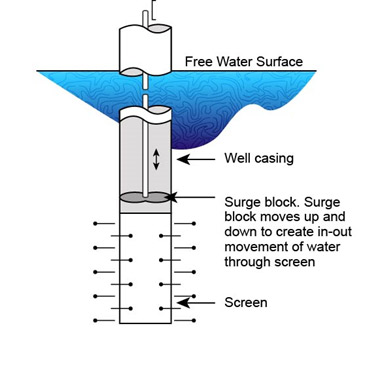

In this method surging action of water loosens minerals and aquifer fines, drawing them into the well for removal. This is often combined with air-lift pumping to remove fines from the well.

Description of the above image

A cross section of a well showing surge block, water surface, well casing and well screen. The surge block moves up and down to create in-out movement of water through the screen.

High pressure jetting

High pressure/jetting assists in dislodging plugging material from the well intake area. This is generally combined with air-lift pumping to remove the loosened material from the well.

Chemical cleaning methods

A number of different types of chemical products are used to remove mineral or biofilm deposits:

- Mineral Acids: dissolve mineral precipitates, such as calcium, iron and manganese

- Organic Acids: dissolve organic compounds, such as biofilms

- Surfactants: improve penetration of treatment chemicals for biofilm removal

- Dispersants: prevent the reformation of minerals or biofilms and keep materials in suspension for easier removal

- Proprietary products: formulated products that contains a combination of treatment chemicals designed for specific applications

| Acid | Carbonate Scale Deposit |

Sulphate Scale Deposit |

Iron/Mn Scale Deposit |

Biofilm Deposit |

|---|---|---|---|---|

| Sulfamic Acid | Very Good | Good | Fair | Poor |

| Hydrochloric Acid | Very Good | Good-Poor | Very Good | Poor |

| Phosphoric Acid | Very Good | Good-Poor | Good | Poor |

| Hydroxyacetic Acid | Poor-Fair | Very Poor | Good | Moderately Good |

| Citric Acid | Poor | Very Poor | Chelates | Poor |

| Oxalic Acid | Very Good | Good | Good | Moderately Good |

The following should be considered when applying chemical treatments:

- Well construction details

- Aquifer type

- Concentrations of various chemicals

- Sequencing of chemicals

- Residence time

- Relative temperatures of the groundwater and treatment chemicals

Well redevelopment

After a well treatment process has been completed, the well must be redeveloped to remove the plugging material that has been disrupted, loosened or broken-up, and any remaining treatment chemicals. Redevelopment methods include over pumping the well, mechanical bailing, surge blocking/swabbing and air-lift pumping to restore the well capacity.