and water quality concerns.

For years, producers have been watering cattle and other livestock throughout the winter months by cutting holes in the ice. Even though livestock receive water, there are a number of long term problems associated with this watering practice. Livestock death by drowning or exposure can be a significant problem. Losing an animal through the ice can result in considerable profit loss, as well as enormous stress on the animal if it should survive.

Direct access winter watering also causes manure loading which leads to poor water quality. As the ice melts in the spring, animal excrement introduces disease-causing organisms such as bacteria, viruses, and parasites into the water.

Excrement also introduces nutrients into the water, which in turn can cause excess algae and plant growth during summer months.

Benefits of a remote winter watering system

Remote winter watering systems allow producers to provide water to livestock during the winter outside of the traditional confinement yard while lowering costs and improving field fertility. Such systems decrease potential for leg injuries, fatalities, competition and water quality risks that are found with uncontrolled access to surface water.

The essentials of a remote winter watering system

A winter watering setup will differ from location to location. Choosing a suitable location for a remote watering system is critical. Since most off-site water sources are permanent, some manure accumulation is unavoidable, so it is important to assess and control any runoff potential to ensure that quality of the water is maintained.

Besides the availability of quality water, other factors to consider when choosing a watering site include: distance from the water source, elevation, and shelter.

The overall design of the system will depend on personal preference, reliability, herd size, remoteness, and site location. Other factors to consider are optimum pumping rate, distance between pump and outlets, height difference between outlets and source, and maximum daily water requirement.

Most winter watering systems available on the market today have a common set-up. The main components are an intake water line from the dugout, wet well, power source and pump. Wet wells are installed next to surface water supplies to provide a quick and convenient method for housing a water distribution pump.

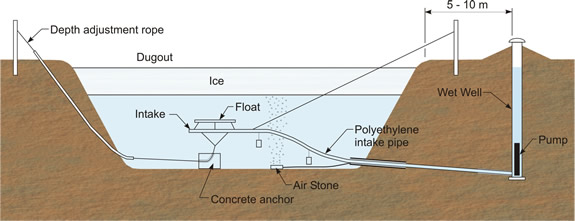

Description: Schematic of a winter watering system

A winter watering system showing a dugout with a layer of ice. Under the ice the water intake system is held in place by a float and a concrete anchor and can be adjusted with a depth adjustment rope that attaches the system to a post on the bank of the dugout. The intake is connected to a pump at the bottom of the wet well by a polyethylene intake pipe. This pipe also connects to an air stone that sits at the bottom of the dugout and releases air into the water. The wet well is 5-10 meters from the edge of the dugout.

The creation of an elevated mound around the wet well is recommended. This gentle sloping mound will act as an insulator and aid in the prevention of frost build-up. The mound could also assist with local surface drainage ensuring a dry, clean, safe watering site.

A floating intake system is recommended to remove the best quality water from the source. Before freezing, the float should be lowered below the expected ice level.

Water flows by gravity from the dugout, through the intake, and into the wet well.

Pumping system options

Technological advances in the use of natural energy sources such as geothermal heat and solar and wind power allow producers many options for pumping the water from the wet well and protecting the water from freezing.

Every system has its strengths and weaknesses. Descriptions of a few of the most common types follow:

Door switch

switch located on the door frame. A self

draining basin returns water to the wet

well.

This system is set up directly over a wet well. When an animal pushes open the trough door a switch is activated which runs the pump located near the bottom of the wet well. Water is then moved up to the trough. Situated near the back of the trough is a screened overflow return line.

The water level in the trough is regulated by the height of the overflow return line. A time delay is built in to avoid pump cycling. The pump will run for a preset time after the door is closed. This allows the second animal to follow and receive a drink of water. After the animals have finished drinking, the pump shuts off. A series of small drain holes are located at the base of both the discharge and overflow return lines. These holes allow the water to drain back into the wet well so that no water remains in the trough to freeze.

Producers who use this type of system have found that livestock will adapt to it in a couple of days.

Motion detector water pump-up system

pumps water into a basin as livestock

approach.

This system uses a motion sensor to activate the pump. A double walled round watering bowl is located on top of the wet well. When an animal walks up to the drinking bowl, an electronic motion detector turns on a pump that fills into the bottom of the bowl. The water level rises in the basin to a set of overflow holes that return excess water back into the wet well.

These holes are located near the top edge of the trough to prevent overflow onto the ground.

The pump will run as long as there is motion within the range of the motion detector. To prevent the pump from starting and stopping, a delay is built in to allow the pump to continue running for a preset time. This delay allows the next animal to approach the basin and get water before the pump shuts off.

Water remaining in the basin will return to the wet well through the bottom of the trough so that no water remains in the basin to freeze. A filter prevents debris from going back down into the pump with the water. Motion detection systems are adaptable to a variety of setup configurations.

The filter must be cleaned regularly to ensure that water can drain back and prevent freezing of the bowl and supply line. If kept in good condition, these pump-up systems work very well and do not freeze.

Air circulation

(by air or water) in an insulated trough.

In this system water is pumped water from the wet well into an insulated, doughnut-shaped trough. A small air compressor operates continuously to prevent the water from freezing. The compressor draws warm air from the wet well and injects it near the access hatches and float switch. The float switch signals the pump when the water level is low to keep the trough full.

Livestock drink water through access hatches in a fitted, insulated lid that sits atop the wet well. The air circulation system takes advantage of the ground's natural warmth so no additional heat is required. Other benefits to the air circulation system include the facts that the addition of air improves water quality, more than one animal can drink at a time, and no water returns to the source.

On extremely cold nights all but one of the access hatches may have to be covered to prevent heat loss.

Solar portable ice-free waterer

All of these above-mentioned systems can use solar energy. Solar energy is an efficient, environmentally friendly, relatively inexpensive way of providing power to remote locations. The direct-current (DC) storage batteries that run the wet well pump must be protected from the cold. Warm batteries charge easily and give more power when needed.

A discarded household chest freezer makes an excellent battery storage compartment and will protect the batteries when buried in the ground and covered with straw and/or snow.

Portable ice-free waterer

In this system, a small, highly-insulated, portable building encloses a poly tank that holds hundreds of gallons of water, several degrees above freezing. Animals drink from a water trough which only has a small area situated outside the building. The buildings temperature is moderated by the latent heat of the water.

This system works best if most, if not all, of the water in the tank is exchanged daily. If all of the water is not consumed and exchanged with new water, it will cool and the system will begin to freeze, starting with the drinking area.

This system works very well when the building is well insulated, as the overnight temperature dip will not affect the indoor temperature significantly. This system should have enough animals drinking so that at least 1,300 litres (300 gallons) of water are consumed and replaced daily. Fresh water each day will overcome the cooling effect from the drinking holes and building temperature losses.

Some ice may need to be cleared from the drinking tubes on very cold days, but generally no other maintenance is needed. The best part of this system is that the interior of the building stays above freezing, and batteries, and/or gasoline powered generators located within the building work more efficiently. In addition, this small building can be hoisted onto a bale mover and hauled to other well locations as required.

Mining tire geothermal waterer

In this system, livestock drink from a water trough made from a used industrial mining tire. Water is provided through a buried supply line from an existing water system. The tire pit is buried below ground level which allows for geothermal heat to rise, which helps to keep the supply line thawed and the bottom of the drinking trough warm.

This process works best with very thick rubber tire faces. As rubber thickness increases, the R-insulating value of the trough also increases. In cold weather, the float will freeze into a layer of ice which will need to be cleared daily. But if this system is built properly, the geothermal warmth will keep the supply line below the trough free of ice during the coldest weather.

However, where the supply line passes up through the frost line in the soil is the most likely place the system will freeze.

The mining tire trough will generally have a layer of ice each morning which will need to be cleared. Once the ice is cleared, livestock drinking activity will keep the trough free of ice for the remainder of the day. There must be enough animals drinking from the trough to completely replace all the water every day, otherwise the water will get colder and eventually freeze solid.

This system is well suited for deep-burial pipelines that travel great distances underground - too far to carry electricity lines for heaters.

Geothermal ice-free waterer

In this system, livestock drink directly out of a drinking tube located at the top of a 1.2 metres (m) (4.0 feet (ft)) diameter insulated galvanized culvert. The 3.0 m (10 ft) culvert is installed vertically with 2.4 m (8.0 ft) buried below ground level. Geothermal heat and the latent warmth of the water helps keep the small diameter drinking tube free of ice, even in cold weather.

The water supply pipe enters the bottom of the culvert below the frost line, and rises up the middle of the culvert under an insulated lid. A float valve controls the water height which needs to be within 7.6 to 12.7 centimetres (cm) (3.0 - 5.0 inches) of the top of the culvert so that livestock can easily reach the water.

These units work well with minimal management and are ideal for long-run underground water supply pipelines. In some situations, deep pipelines have been installed running over 1.61 kilometres (km) (one mile) from the water supply.

The major advantage of these units is that once they are set up, there is minimal upkeep cost, no electricity bills and no heaters required to keep the water clear of ice. The largest limitation is that under exceptionally cold weather, the drinking tube may develop an ice plug in the drinking hole which will need to be cleared.

These units can also be adapted to DC-powered deep well pumps and drilled well situations with little modification.