Luna Yu is solving both food waste and plastic pollution with the help of bacteria

With the increase of regulations to limit plastic use, companies struggle to find green alternatives that don’t break the bank. There isn’t an abundance of choices. Luna Yu, co-founder and CEO of Genecis Bioindustries, is set to change that with a biodegradable plastic she creates from food waste. All it took was a rice cooker and some brain power.

A first exposure

Luna’s love for the environment and biology led her to the University of Toronto where she completed a Bachelor and a Master of Science. Like many students, she took on a few side jobs during her studies, but with a goal in mind. She worked in sales to learn about the business world because she was highly motivated to start her own business, which she did founding Genecis Bioindustries right after her graduation.

Luna wanted to create a company to “use biology to make something new and better”. Her inspiration: the biogas industry which converts food waste into fuel. She wanted to push the limits as to what else could be done with food waste. Aware that literally tons of food go to waste every year, she hoped to find a sustainable way to make use of it.

Humble beginnings

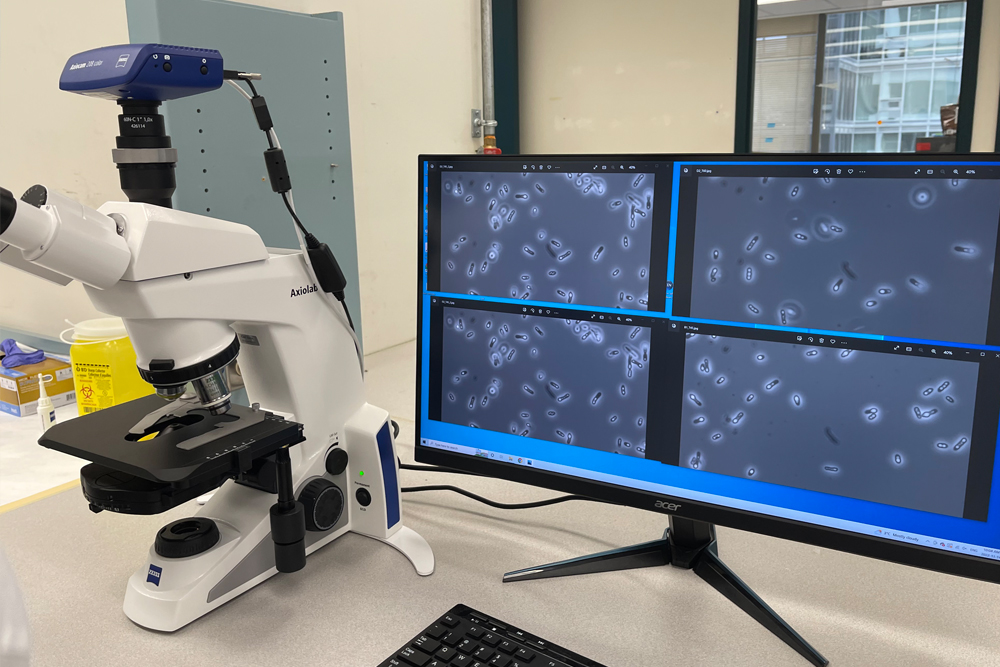

The real “cooking” began in 2017 when Luna gathered a team of recent graduates from different backgrounds but sharing a common vision: making the world a better place. They reviewed past studies to find out how they could use the carbon in food waste and make something new out of it. The answer? Polyhydroxyalkanoate or (PHA). PHA is a kind of fat created by bacteria when they “eat” food waste and has plastic-like properties.

Now that they found a way to transform food waste into a biodegradable plastic, the next step was to start growing the bacteria. However, without a laboratory and sufficient funds, buying expensive bioreactors was out of the question. Creativity was the only key to solve this challenge. Luna and her team started brainstorming ideas to replicate a bioreactor that would cost very little money. The device would need a closed tank that they could modify with sensors, mixers and automation control to have it resemble a bioreactor.

They first tried to use a pressure cooker, but that didn’t work: it heat up too quickly and killed the bacteria. The next option was a rice cooker. After a month and a half retrofitting 7 rice cookers, they saw a glimmer of hope.

By the end of the summer, what came out of their experiment was not rice, but their very first flakes of PHA bioplastics from fermented food waste. “It was less than a gram, but proved the basic concept that you can do that with the carbons from food waste,” says Luna, who will never forget that memorable day. With their experiment confirming their concept, Genecis Bioindustries was ready to revolutionize the world. All they needed was to figure out how to increase volume.

Scaling up

Genecis Bioindustries was on the lookout for financial support to step up their project. When the Food Waste Reduction Challenge was recommended to her through her network, Luna decided to apply – a decision she doesn’t regret, as it helped her reach her milestones bit by bit. “The challenge really drove us into that direction of going from laboratory scale to then pilot scale and then eventually demonstration scale at a biogas plant,” Luna says.

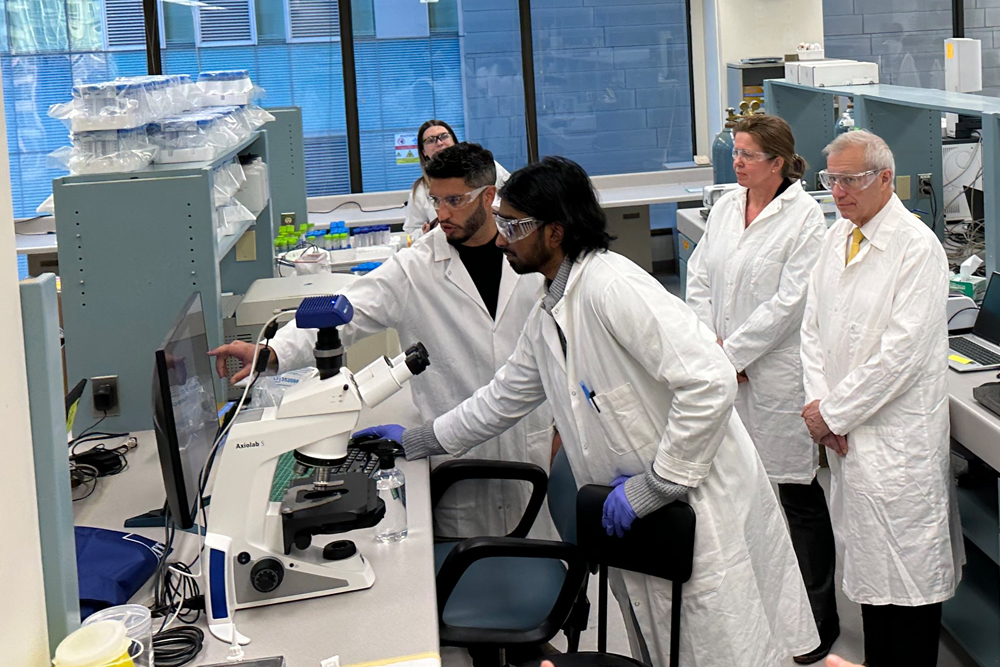

Their current workplace now looks a lot less like a kitchen and more like a professional laboratory, located in downtown Toronto with a pilot facility in Scarborough. They have research partnerships with institutes and many universities in Canada, the United States, and Europe. No longer dumpster diving to collect food waste, they get it directly from their partner biogas plants who receive hundreds of tons of food waste daily.

Luna is working towards making Genecis Bioindustries a functional commercial plant producing steady revenues with everyday products soon to be available for consumers. She also plans to continue experimenting with other organic waste disposed of in large amounts and making the most of the potential of PHAs. With technology and the development of artificial intelligence, the possibilities are endless to help reduce food waste and plastic pollution.

Genecis Bioindustries is a Novel Technologies winner of the 2024 Food Waste Reduction Challenge.

What is PHA?

Polyhydroxyalkanoate (PHA) are biopolymers produced by microorganisms, like bacteria, through fermentation. When extracted from the bacteria, PHA has the same properties as plastic but is biodegradable, making it a more environmentally friendly option. PHA can be molded into a plastic bottle and safely thrown back into nature to break down naturally, eliminating any chance for waste, harmful microplastics, or toxic residue.